How to Insulate a Metal Building to Prevent Condensation and Temperature Swings

Metal building condensation creates rust, damages equipment, and makes spaces uncomfortable. Whether you own a workshop in Apex, a warehouse in Garner, or a pole barn in Holly Springs, understanding how to insulate a metal building properly protects your investment and maintains comfortable temperatures year-round.

At Energy Saving Insulation, we've helped hundreds of property owners across Raleigh and surrounding communities solve these exact problems with professional spray foam insulation solutions designed specifically for metal structures.

Why Metal Buildings Develop Condensation Problems

Metal building condensation occurs when warm, humid air contacts cold metal surfaces. North Carolina's climate creates perfect conditions for this issue, especially during temperature swings between day and night or across seasons.

Uninsulated metal buildings experience dramatic temperature fluctuations. Summer heat turns workshops into ovens while winter cold makes them unusable. The thermal bridging through metal panels and framework allows heat transfer that drives up energy costs and creates moisture problems throughout the structure.

The Best Insulation Methods for Metal Buildings

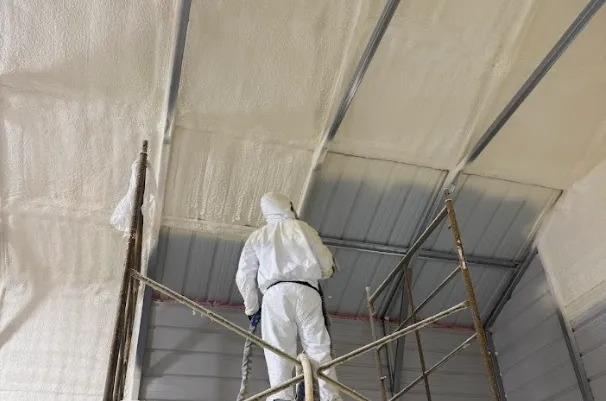

Spray foam insulation provides the most effective solution for metal building insulation. Unlike traditional fiberglass batts that leave gaps and allow air movement, closed-cell spray foam creates a complete air seal directly bonded to metal surfaces.

Closed-cell spray foam delivers superior performance with an R-value of approximately 6-7 per inch. This dense foam creates a moisture barrier that prevents condensation while adding structural strength to your building. For metal buildings in humid climates like Central NC, this moisture resistance proves essential for long-term protection.

Open-cell spray foam offers another option for interior applications where moisture concerns are less critical. With an R-value around 3.5-4 per inch, it provides excellent air sealing and sound absorption at a lower cost per square foot. Many workshop owners in Raleigh and Apex choose open-cell for interior spaces while using closed-cells on exterior walls and roofing.

Professional Application Techniques for Metal Structures

Proper metal building insulation requires specialized equipment and expertise. Professional insulation contractors apply spray foam directly to metal panels, creating seamless coverage that eliminates thermal bridging through purlins and girts.

The application process starts with surface preparation. Metal surfaces must be clean and dry before spray foam installation. Our certified technicians assess your building's specific needs, considering factors like building use, climate exposure, and budget requirements for properties throughout Garner, Holly Springs, and surrounding areas.

Spray foam insulation expands to fill every gap and cavity, creating the airtight seal necessary for condensation prevention. This complete coverage stops air infiltration that causes temperature swings and moisture accumulation in metal buildings.

Addressing Common Metal Building Insulation Challenges in Raleigh and Surrounding Areas

Many metal building owners attempt DIY solutions with fiberglass batts or low-density foam kits. These approaches consistently underperform because they leave air gaps, compress over time, and fail to address thermal bridging through the metal framework.

Professional spray foam contractors understand how to properly insulate around structural elements, doors, windows, and penetrations. We ensure complete coverage while maintaining proper ventilation requirements for your specific building type and use.

The investment in professional metal building insulation pays dividends through reduced energy costs, eliminated condensation damage, and comfortable year-round temperatures. Property owners in Raleigh, Apex, Garner, and Holly Springs typically see energy cost reductions of 30-40% after proper spray foam installation.

Choosing the Right Insulation Solution for Your Building

Every metal building presents unique requirements based on size, use, and location. Agricultural buildings need different solutions than commercial warehouses or residential workshops. Our team evaluates these factors to recommend the optimal insulation solution for your specific situation.

Closed-cell spray foam works best for buildings requiring maximum moisture resistance and structural enhancement. Warehouses, cold storage facilities, and buildings in high-humidity areas benefit most from this premium option available throughout Central NC.

Open-cell spray foam provides excellent value for interior applications where soundproofing matters. Workshop owners appreciate the acoustic benefits while enjoying improved temperature control and reduced energy bills.

Professional Metal Building Insulation Installation Ensures Long-Term Performance

Energy Saving Insulation brings over 20 years of combined experience to every metal building insulation project. Our BBB A-rated company serves Raleigh, Apex, Garner, Holly Springs, and surrounding communities with certified technicians trained in proper spray foam application techniques.

We use professional-grade equipment and materials that deliver consistent results. Our closed-cell and open-cell spray foam products meet or exceed industry standards for R-value, moisture resistance, and durability. Every installation includes detailed documentation proving proper coverage and thermal performance.

Don't let condensation and temperature problems compromise your metal building.

Contact Energy Saving Insulation at (984) 315-7499 for a free consultation. We'll assess your building's specific needs and provide a custom solution that delivers lasting comfort, protection, and energy savings for your property in Raleigh, Apex, Garner, Holly Springs, and nearby communities.

Metal Building Insulation FAQs

What causes condensation in metal buildings?

Condensation forms when warm, humid air contacts cold metal surfaces, creating moisture that leads to rust and damage. Proper spray foam insulation eliminates this by creating a thermal barrier and air seal.

Is spray foam better than fiberglass for metal buildings?

Yes, spray foam creates a complete air seal and bonds directly to metal surfaces, while fiberglass batts leave gaps and don't prevent air infiltration. Spray foam also provides superior R-value and moisture resistance.

How much does it cost to insulate a metal building with spray foam?

Costs vary based on building size, foam type, and coverage area, typically ranging from $1.50-$3.50 per square foot. Most property owners see 3-5 year payback through energy savings.

Can I install spray foam insulation myself in my metal building?

DIY spray foam kits rarely achieve proper coverage and performance due to equipment limitations and application expertise required. Professional installation ensures complete air sealing and proper R-value.

How long does spray foam insulation last in metal buildings?

Professional spray foam insulation lasts 30+ years when properly installed, maintaining its R-value and air sealing properties throughout its lifespan. It won't sag, settle, or degrade like traditional insulation.