Closed-Cell vs Open-Cell Spray Foam for Metal Building Insulation in NC

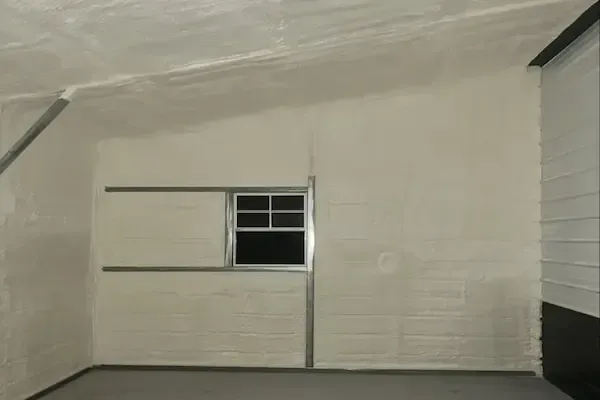

Choosing between closed-cell and open-cell spray foam for your metal building significantly impacts performance, cost, and long-term results. Property owners throughout Raleigh, Apex, Garner, and Holly Springs face this decision when addressing metal building insulation needs.

Understanding the differences between these spray foam insulation types helps you make the right choice for your workshop, warehouse, or agricultural building in Central North Carolina.

Key Differences Between Closed-cell and Open-cell Spray Foam

Closed-cell spray foam creates a dense, rigid barrier with exceptional moisture resistance. This premium insulation material delivers an R-value of 6-7 per inch, making it the most efficient option available for metal buildings. The foam's closed-cellular structure prevents water penetration while adding structural strength to your building.

Open-cell spray foam offers a softer, more flexible solution with an R-value around 3.5-4 per inch. This spray foam insulation expands more during application, filling cavities completely while providing excellent sound absorption. The open-cellular structure allows some moisture permeability, making proper vapor barrier consideration important for certain applications.

Both spray foam types create superior air sealing compared to traditional fiberglass insulation, but their different properties make each ideal for specific situations in metal building applications across Central NC.

Moisture Control and Vapor Barrier Properties

Closed-cell spray foam functions as both insulation and vapor barrier in one application. This characteristic makes it ideal for metal buildings in North Carolina's humid climate. The foam prevents condensation from forming on metal surfaces, eliminating rust and corrosion issues that plague improperly insulated structures in Raleigh and surrounding areas.

The moisture barrier created by closed-cell foam protects against water intrusion from exterior sources while preventing interior humidity from reaching cold metal panels. This complete moisture management proves essential for warehouses, cold storage facilities, and any metal building requiring maximum protection.

Open-cell spray foam allows some moisture permeability, requiring additional vapor barrier installation in certain climates and applications. However, its breathable nature can benefit interior applications where moisture management occurs through proper ventilation rather than complete vapor blocking.

R-Value Performance and Energy Efficiency

R-value measures thermal resistance—higher numbers mean better insulation performance. Closed-cell spray foam achieves twice the R-value per inch compared to open-cell, making it ideal when space is limited or maximum energy efficiency is required.

For metal buildings in Apex, Garner, and Holly Springs where roof insulation depth is restricted, closed-cell spray foam delivers superior thermal performance in less space. This efficiency translates to lower heating and cooling costs year-round, with many property owners seeing 35-40% reductions in energy costs.

Open-cell spray foam requires greater thickness to achieve equivalent R-values, but costs less per square foot. When adequate space exists and moisture control demands are lower, open-cell provides excellent value while delivering complete air sealing and significant energy savings throughout Central NC.

Cost Comparison and Budget Considerations

Closed-cell spray foam typically costs $1.50-$2.50 per board foot, while open-cell ranges from $0.65-$1.25 per board foot. However, comparing costs requires considering R-value differences and performance characteristics rather than simple price per square foot.

A metal building insulation project using closed-cell foam at 3 inches delivers R-18 to R-21, while achieving similar performance with open-cell requires 5-6 inches of thickness. Factor in long-term energy savings, moisture protection, and structural benefits when evaluating the investment for your Raleigh area property.

Energy Saving Insulation provides detailed cost analysis during free consultations, helping property owners understand total value rather than just initial material costs. Our 20+ years of experience guides metal building owners throughout Raleigh, Holly Springs, Garner, Apex, Fuquay-Varina, NC and nearby areas toward solutions that deliver optimal return on investment.

Application Considerations for Different Building Types

Metal workshops and hobby spaces often benefit from open-cell spray foam on interior walls and ceilings, providing excellent soundproofing alongside temperature control. The acoustic properties reduce noise transmission, creating more comfortable work environments for properties in Apex and Holly Springs.

Commercial warehouses and storage facilities typically require closed-cell spray foam for maximum moisture resistance and structural enhancement. The foam's rigidity adds racking strength while protecting inventory from temperature and humidity fluctuations common in metal buildings across Raleigh, Holly Springs, Garner, Apex, Fuquay-Varina, NC, and surrounding areas.

Agricultural buildings and livestock barns need careful evaluation. closed-cell prevents condensation that damages equipment and compromises animal health, while open-cell may suffice for buildings with adequate ventilation systems already addressing moisture management.

Professional Closed-Cell and Open-Cell Spray Foam Installation Ensures Optimal Results

Choosing between closed-cell and open-cell spray foam requires expertise in building science, climate factors, and application techniques. DIY attempts with low-density foam kits rarely achieve proper R-values or air sealing performance, often costing more long-term through wasted materials and poor results.

Energy Saving Insulation's certified technicians properly apply both spray foam insulation types using professional-grade equipment that ensures consistent density, thickness, and coverage. Our BBB A-rated company serves Raleigh, Holly Springs, Garner, Apex, Fuquay-Varina, NC, and surrounding communities with insulation solutions tailored to each building's specific requirements.

Free Spray Foam Consultation for Your Metal Building in Raleigh, Apex, Garner, and Holly Springs, NC

We evaluate your metal building's use, exposure, budget, and performance goals to recommend the optimal spray foam insulation solution. Whether you need maximum moisture control with closed-cell or value-oriented open-cell with excellent air sealing, we deliver professional installation that performs as designed.

Contact Energy Saving Insulation at (984) 315-7499 for expert guidance on closed-cell vs open-cell spray foam for your metal building. Our free consultation provides clear answers about which solution best serves your property in Raleigh, Holly Springs, Garner, Apex, Fuquay-Varina, NC, and nearby areas.

FAQs Open-Cell vs Closed Cell Spray Foam Insulation

Which spray foam is better for metal buildings in humid climates?

closed-cell spray foam performs better in humid climates because it creates a complete vapor barrier and prevents moisture penetration. This makes it ideal for North Carolina's climate where condensation control is critical.

Can I use open-cell spray foam on metal building exteriors?

open-cell spray foam works best for interior applications due to its moisture permeability. Exterior applications require closed-cell spray foam's vapor barrier properties to prevent moisture damage.

How much thicker does an open-cell need to be compared to closed-cell?

open-cell requires approximately 1.5-2 times the thickness of closed-cell to achieve similar R-values. For example, 3 inches of closed-cell (R-18) equals about 5 inches of open-cell.

Does closed-cell spray foam really add structural strength to metal buildings?

Yes, closed-cell spray foam's rigid structure adds significant racking strength to metal building frames. Studies show it can increase structural integrity by 200-300% when properly applied.

Which spray foam type offers the best return on investment?

ROI depends on your specific needs—closed-cell delivers maximum energy savings and moisture protection, while open-cell provides excellent value when space allows. Most metal building owners see 3-5 year payback periods with either option.